The fashion industry is one of the largest contributors to global waste, with tons of fabric discarded at every stage of production. Zero-waste pattern making is a transformative approach designed to eliminate textile waste before a garment even reaches the cutting table. By rethinking design and construction, this method creates stylish, functional garments while reducing environmental impact.

Zero-waste pattern making is not just a trend — it’s a movement toward a more responsible, circular, and innovative fashion industry, aligning with broader sustainability initiatives like Waterless Denim Innovations.

What Is Zero-Waste Pattern Making?

Zero-waste pattern making involves designing patterns in a way that uses every inch of fabric, leaving no leftover scraps. Traditional garment production typically wastes 10–30% of fabric per piece, which contributes to landfills and resource inefficiency.

The approach requires careful planning, creativity, and often digital design tools. Designers work to integrate seams, folds, and geometric shapes to optimize fabric usage while maintaining aesthetic appeal and comfort.

Key Principles of Zero-Waste Pattern Making

- Geometric Optimization: Patterns are designed to interlock like puzzle pieces, ensuring minimal waste.

- Multi-Functional Pieces: Garments often use panels or folds that serve multiple structural or decorative purposes.

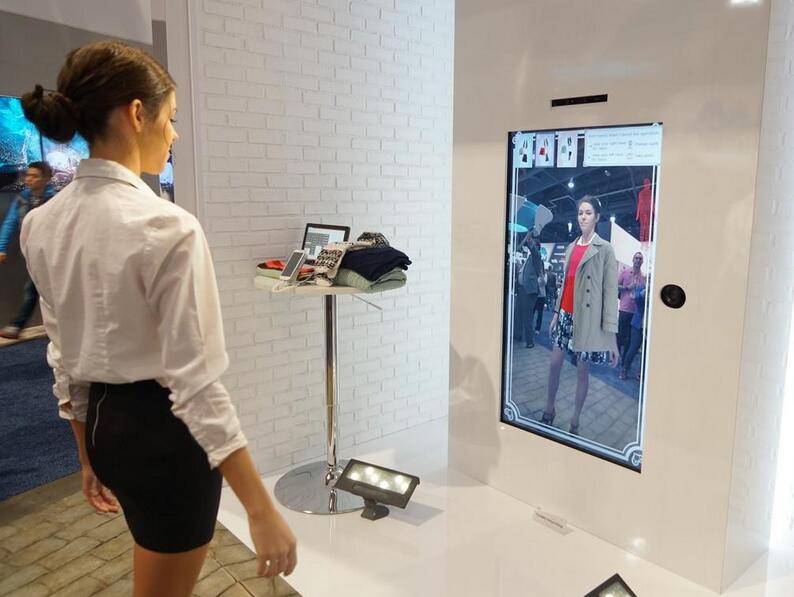

- Digital Tools: CAD software helps designers visualize fabric layouts and maximize efficiency.

- Circularity: Garments are designed to be repurposed, recycled, or upcycled at the end of their lifecycle.

Table: Traditional vs. Zero-Waste Pattern Making

| Feature | Traditional Pattern Making | Zero-Waste Pattern Making |

|---|---|---|

| Fabric Usage | 70–90% | 100% utilization |

| Waste | High (10–30% per garment) | Minimal to none |

| Design Flexibility | Moderate | Requires creative optimization |

| Environmental Impact | Higher water, energy, and chemical usage | Reduced waste, lower carbon footprint |

| Tools | Manual drafting, basic CAD | Advanced CAD, digital simulation, innovative folding techniques |

Techniques in Zero-Waste Pattern Making

1. Integrated Pattern Design

Designers create garments where each piece fits perfectly into the next, similar to a jigsaw puzzle. For example, sleeves may form part of the bodice, and facings double as pockets. This integration reduces scrap fabric without compromising style.

2. Modular Clothing

Modular garments use repeated shapes and panels that can be rearranged or extended to create different styles. This flexibility allows a single fabric cut to produce multiple designs, minimizing waste.

3. Digital Optimization

Advanced computer-aided design (CAD) software simulates fabric layouts and adjusts patterns to eliminate gaps. This method allows precise planning, which was nearly impossible with traditional drafting.

4. Upcycling and Patchwork

Zero-waste designers often repurpose leftover scraps into new garments, accessories, or decorative elements. Patchwork, pleats, and pleating folds can transform minimal waste into design features.

5. Creative Folding and Cutting

Innovative cutting methods, like rotational or origami-inspired techniques, make full use of every fabric inch. This approach often results in visually striking and functional garments that are both sustainable and fashionable.

Advantages of Zero-Waste Pattern Making

- Environmental Impact Reduction: Fewer scraps mean less landfill contribution and lower resource waste.

- Cost Efficiency: Optimized fabric usage can reduce production costs for brands and consumers.

- Innovative Aesthetic: Zero-waste designs often feature unique shapes, folds, and textures, distinguishing them in the market.

- Supports Circular Fashion: Garments are easier to recycle, repair, or repurpose, extending their lifecycle.

- Compatibility with Other Sustainable Practices: Zero-waste pattern making complements innovations like Waterless Denim Innovations, organic fabrics, and biodegradable materials.

Leading Brands and Designers

Several brands and designers are at the forefront of zero-waste pattern making:

- Tonlé: Specializes in zero-waste collections using hand-cut fabrics and modular designs.

- Mara Hoffman: Integrates zero-waste principles into luxury, ready-to-wear collections.

- Zero Waste Daniel: Combines creativity and sustainability by transforming scrap fabrics into high-fashion pieces.

These pioneers demonstrate that ethical design doesn’t mean sacrificing aesthetics or quality.

Challenges in Zero-Waste Pattern Making

Despite its advantages, zero-waste pattern making faces several obstacles:

- Design Complexity: Requires advanced planning and creativity to ensure both style and efficiency.

- Production Costs: Initially, the process may be more expensive due to longer design and testing phases.

- Material Limitations: Certain fabrics, especially stretch textiles, may be harder to optimize without waste.

- Market Education: Consumers may need awareness about the value and impact of zero-waste garments.

As the industry invests in training, digital tools, and innovation, these barriers are steadily decreasing.

Table: Environmental Benefits Comparison

| Aspect | Traditional Production | Zero-Waste Pattern Making |

|---|---|---|

| Fabric Waste | 10–30% per garment | Close to 0% |

| Water Use | High (for cotton and finishing) | Lower due to reduced material use |

| Energy Use | Higher for washing and cutting | Reduced due to optimized layouts |

| Carbon Footprint | Moderate to high | Significantly lower |

| Circularity | Limited | Designed for repurposing and recycling |

FAQs About Zero-Waste Pattern Making

Q1: What types of fabrics are best for zero-waste pattern making?

Woven fabrics like cotton, linen, and wool are easier to optimize, though innovative techniques now allow stretch and mixed fabrics to be used effectively.

Q2: Does zero-waste mean the garment has no seams?

Not necessarily. Zero-waste focuses on using the entire fabric efficiently; seams are often strategically placed and can be part of the design aesthetic.

Q3: Can zero-waste techniques be applied to mass production?

Yes. With digital tools and optimized cutting layouts, zero-waste methods can scale to industrial manufacturing while maintaining sustainability.

Q4: How does zero-waste pattern making relate to other sustainable practices?

It complements waterless production, organic or recycled fabrics, and circular fashion initiatives, creating a holistic approach to sustainable design.

Q5: Are zero-waste garments more expensive?

Initially, yes, due to design complexity, but long-term benefits include cost savings from reduced fabric waste and marketing appeal to eco-conscious consumers.

The Future of Zero-Waste Pattern Making

Zero-waste pattern making represents a fundamental shift in how fashion is conceived, designed, and produced. By prioritizing material efficiency and sustainability, designers can create garments that are not only beautiful but environmentally responsible.

As brands adopt technologies like digital patterning, modular design, and laser cutting, zero-waste fashion will become more accessible, scalable, and innovative. When combined with other innovations, such as Waterless Denim Innovations, the industry can achieve remarkable reductions in water usage, chemical exposure, and textile waste.

This holistic approach ensures that fashion continues to thrive creatively while respecting ecological limits. In the coming years, zero-waste pattern making may become the new standard — a necessary step toward a truly sustainable and ethical fashion future.

Zero-waste pattern making proves that sustainability and style are not mutually exclusive. With creativity, technology, and conscious production, every inch of fabric can be transformed into something meaningful, functional, and beautiful — leaving nothing behind but a better planet.